- 11.11.2022

- Tank & Line Testing, Installation Testing

UST fuel leak detection for fast, accurate, digitally verified results

Find a Partner

While UST systems are out of sight, they cannot be out of mind.

One small, undetected leak can become one big problem for UST owners and operators. Lines especially are the most vulnerable part of a UST system, with 70% of all leaks occurring in line fittings, welds and joints.

The US EPA estimates the average cleanup cost at a fouled fueling site is $130,000. And costs to remediate leaks that affect groundwater supply can range from $100,000 to $1 million.

When it comes to fuel leak detection, accuracy matters. Leighton O’Brien’s precision tank and line test is the fastest, most accurate method of fuel leak detection. There is no leak scenario our test method cannot detect.

Our dry line test is certified to a leak rate of 0.025 gph – 400% more accurate than required US EPA requirements – protecting the integrity of your fuel system including the most miniscule leak.

See our certification

In the compliance testing market, there’s a huge difference in the quality, accuracy and validity of underground leak detection testing.

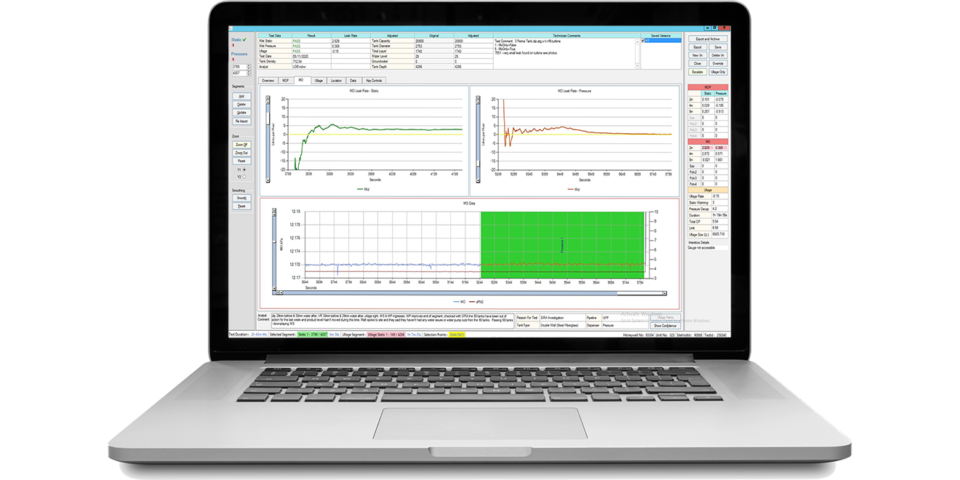

Traditional testing systems use outdated, analog technology that relies on a technician to declare a PASS or FAIL result.

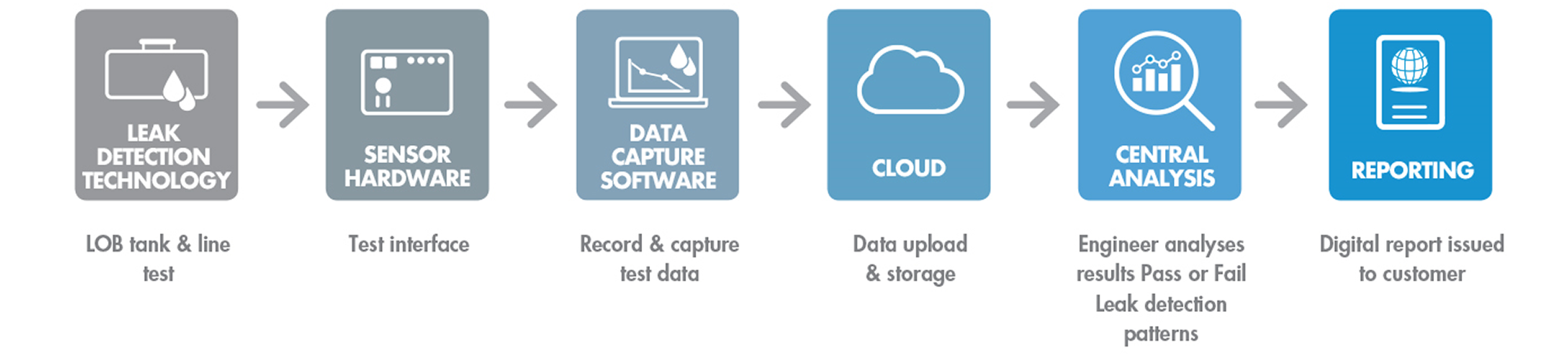

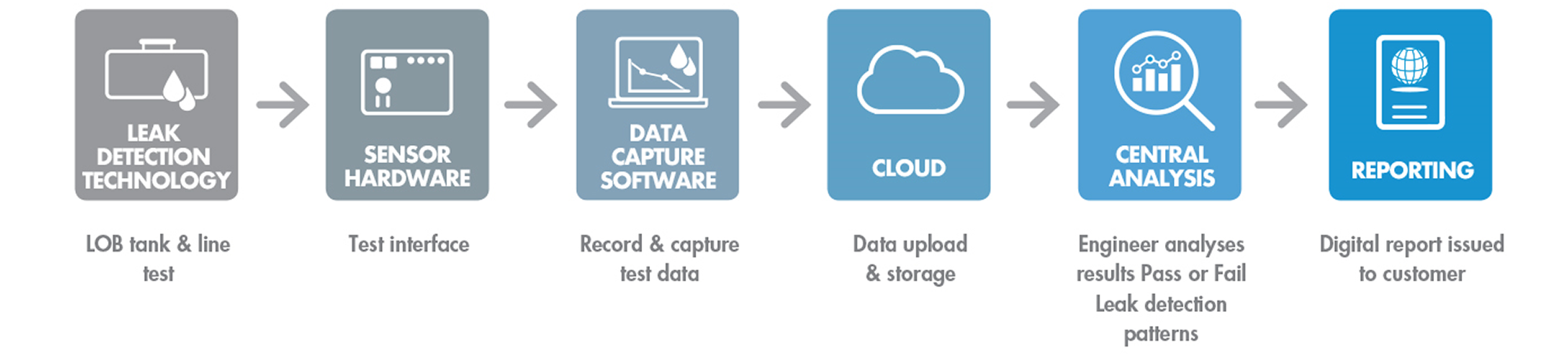

Our digital testing solution changes the paradigm in integrity testing. It is the only test platform that digitally captures test results which are then uploaded to the cloud for analysis by qualified engineers.

The digital signature verifies that the tests have been performed correctly in accordance with EPA standards, ensuring verified compliance for every single test.

Get in touch

This flyer takes a deep dive into precision tank and line testing in the USA

Learn moreWe have high quality partners around the globe with integrity testing expertise. Use our map to find a partner near you.

Find a PartnerFor new site installations, you want to ensure a perfectly tight storage system from day one. We provide certified, accurate testing technology at the pre-bury and post-bury stage.

Learn moreFor complete testing of lines, containment sumps and leak detectors, Compliance Plus is a single-source digital testing platform that increases site uptime, lowers leak risk and ensures digitally verified compliance with EPA regulations.

Learn more