- 20.11.2023

- SIR, Tank & Line Testing, Cleaning

This article was first published on PetrolPlaza, September 15, 2020.

The Middle East is undergoing significant development regarding environmental awareness, protection and sustainability. Throughout the region, new national environment strategies outline a framework to enhance the effectiveness of the sector, increase environmental compliance and promote private sector participation to improve service quality, boost the economy, spur innovation and protect critical resources.

This in turn, is driving major investment among leading fuel retail networks (and other fuel handling businesses) in environmental risk management programs to ensure their sites operate safely. In addition, as part of their growth strategies, major oil companies are acquiring smaller scale retailers, predicated by robust due diligence to evaluate site infrastructure in terms of asset integrity and maintenance requirements.

Leading global fuel analytics and field technologies provider Leighton O’Brien has partnered with leading service companies throughout the region and its surrounds including UAE, Oman, Lebanon, Pakistan, Iraq, Egypt and Saudi Arabia to provide best-in-class leak detection and fuel restoration solutions for their fuel retail customers.

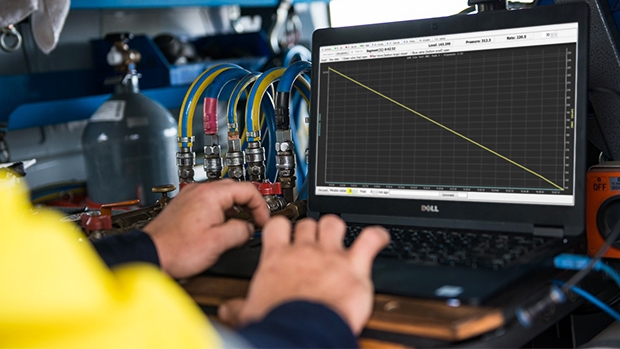

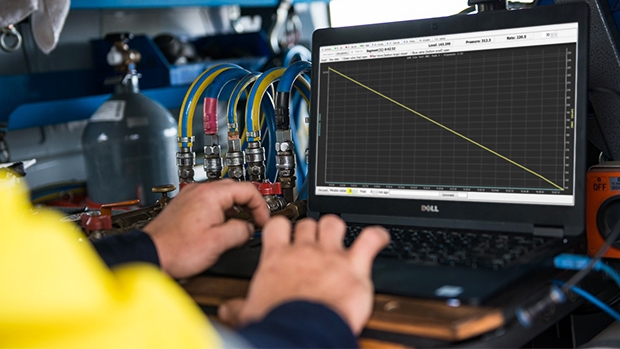

Leighton O’Brien Business Development Manager (EMEA Region), Munir Azizullah, said: “With an increasing focus on environmental sustainability and improving internal best practice standards, fuel retailers are seeing the value of digital leak detection technology that is certified to US EPA protocols.

“As major oil companies continue to acquire and consolidate their retail network, conducting proactive integrity testing of existing underground fuel tanks and lines is a key part of a preventative maintenance program to prevent fuel releases and ensure asset longevity. We also see a situation where our customers are considering the key risks presented by the continued use of dated equipment on their legacy locations.

“Our EPA-certified integrity test is the world’s most accurate method of leak detection; able to detect ullage leaks equivalent to 0.025 gph, without the full shutdown of sites, making it 400 per cent more accurate than traditional leak detection thresholds.

“There is no leak scenario our test cannot detect,” he said.

Data from Leighton O’Brien also indicates a tight correlation between ullage & fitting issues and fuel contamination like water, sludge, rust and biological activity. This causes higher maintenance costs, higher fuel losses and poorer environmental performance.

“In fact, globally between 11% and 42% of fuel systems have ullage issues permitting water to enter the tank. We have seen that sites across the Middle East Africa region tend to represent the higher end of that scale,” Mr Azizullah said.

“Water is the enemy of underground fuel systems. Too often we see the devastating effects of microbial contamination on product quality and tank health.”

Mr Azizullah said that unfortunately, the problem is getting worse due to modern fuel blends which are much more susceptible to the presence of water as they can hold more entrained moisture than fuels from the past.

“A reduction in sulphur content has resulted in environments that are much more tolerable by the microbes allowing them to grow at much higher rates and in parts of the tank not seen with high sulphur content fuels.

Microbial contamination from water ingress almost always results in the corrosion of the metal parts of tanks and/or dispensing equipment and often leads to sludge in the tank. A milestone US EPA study found 83% of tanks containing low sulphur fuels had accelerated and excessive corrosion.

“And while ATG’s are a wonderful tool that provide many benefits, few site operators pay much attention to water indications from the ATG until a water alarm is triggered. Due to limitations in ATG configuration and their inability to detect corrosion, by the time an ATG alarm is triggered, it is often too late.

“If not proactively managed and treated effectively, water ingress can lead to the need for costly replacement of pumps, filters, pipes, dispensers or even whole tank systems. There are also many documented examples where consumers have sought compensation from fuel suppliers for damage to their vehicles,” he said.

Mr Azizullah said ongoing fuel quality monitoring as part of a preventative maintenance program is the first line of defence.

“Site operators should routinely have fuel samples collected from the tank, as well as regularly dip the tank for the presence of water, especially after any bulk delivery.

“For any tank system containing fuel contamination, we offer an advanced tank cleaning and fuel restoration solution for removing contamination and free water as well as a patented process for restoring fuel quality.

“With our patented technology, oil companies can address water intrusion issues, malfunctioning dispensers, blocked filters, bacterial growth, diesel bugs and phase separation.

“In addition, our process does not require manned entry and in most cases fuel sites can remain open which ensures a safe, fast, effective cleaning process with minimal waste.”

Contact us for further information