- 30.09.2021

- Cleaning

Tank cleaning: US study reveals growing issue of microbial related corrosion in diesel tanks

Articles

Tank cleaning: US study reveals growing issue of microbial related corrosion in diesel tanks

By Jason Park – General Manager, Service Distributors

Further to our last blog post on the impact of modern fuel formulations on storage tank integrity, the US PEI Association recently published a paper on microbial related corrosion of diesel storage tanks. It follows an investigation at UST facilities at the Dallas/Forth Worth airport.

The study recommended a number of solutions to minimise the ongoing corrosion of the tank, tank top fittings and pumping components.

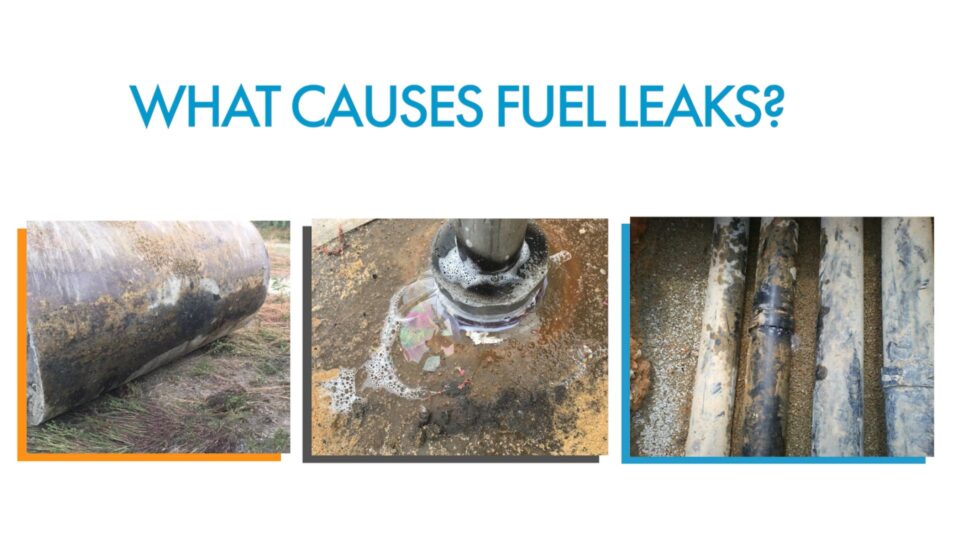

As touched on in our last blog post, the increasing occurrence of microbial related corrosion in diesel tanks has been globally recognised by the petroleum industry over the last 10 years. Corrosion is commonly occurring not only in the fuel carrying area of tanks but in the ullage space and throughout the steel components of the tank top and pumping assembly. Often initially apparent though slow pump flows and more frequent pump filter changes, further investigation usually leads to the discovery of contamination and corrosion throughout the fuel system including areas that may never come into contact with fuel.

Without considering the potential of lost sales caused by slow or non-functioning pumps, microbial corrosion almost always leads to significantly increased OPEX spend by having to regularly clean or change filters, corrosion damage to pumping components and eventually replacing pumping. Not forgetting an increased potential for breach of containment.

The US study reveals that microbial corrosion can’t be controlled by a one off treatment, but requires an ongoing maintenance program, with a focus on clean and water free tank environments. The presence of water in a tank is considered the most critical factor in the growth of corrosion causing microbial activity. As little as 1/4 inch of water (6.35mm) of free water can dramatically increase microbial activity in a tank and subsequently accelerate corrosion in the fuel system.

Initially developed to prepare tanks for the introduction of ethanol fuels to the Australian market in the mid-2000s, Leighton O’Brien’s tank cleaning and fuel restoration technology is ideally suited to mitigate the risks of microbial related diesel corrosion.

Industry-wide awareness of the incompatibility of water with ethanol based fuels drove our engineers to develop a solution that could ensure ethanol systems were 100% clear water and particulate before commissioning. This same technology is ideally suited to treat diesel microbial contamination in tanks because of its ability to remove 100% of water from the entire length of the tank floor, as well as solid particulate and dead microbial growth, thus mitigating the environment for new growth to occur.

Our programmed maintenance solution for ongoing management of microbial related corrosion in diesel tanks involves:

- An initial chemical treatment of the tank, tank cleaning, line flushing and fuel treatment and restoration.

- Weekly onsite water readings from ATG or dewatering point

- Monthly dead-bottom sampling and analysis

- Annual tank cleaning and fuel restoration to ensure all water (free phase and suspended) and particulate is removed from the tank

Contact Leighton O’Brien to discuss any microbial related corrosion issues your tank system or network may be experiencing.