- 27.09.2022

- iHUB

Repair or replace: how will you address the aging tanks?

News

Repair or replace: how will you address the aging tanks?

A few weeks ago, Fuel Market News published the article: The Pros and Cons of Tank Replacement.

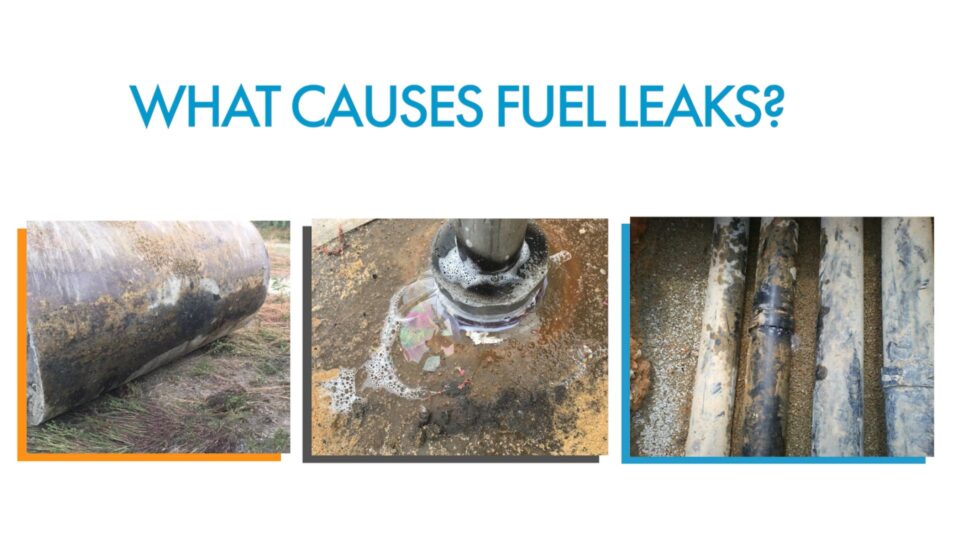

As explained by the author, with more than 150,000 underground storage tanks (USTs) expected to hit the 30-year mark in the next decade or so, the fueling industry is embarking on a period of significant activity to address the aging vessels.

UST owners face two basic choices: keep their existing assets or replace them.

If you are facing this dilemma, we’d like to provide some thoughts on how technology can help in different scenarios to meet regulations and ensure that your equipment and investment will be protected.

Risk assessment: setting an action plan

Technology can play a key role in helping UST owners perform a complete risk assessment of all the existing assets and understand which are worth repairing or replacing.

This can be done in our fuel management platform, iHUB, through the Fuel Asset Tracker tool.

This module enables centralized document storage and tracking of fuel system components including tanks, pumps, equipment and dispensers allowing fuel retailers to identify trends in asset reliability and repair costs and assist with technician and vendor management and maintenance invoicing.

By having access to all the information in one place, UST owners can get full visibility and gather relevant insight to assess the risk of the life cycle of the fuel system assets.

Keep the existing tanks

Let’s say that after performing a risk assessment you decide to keep the existing assets.

As explained by the author in Fuel Market News, obtaining coverage for tanks that are approaching or have surpassed their warrantied service life will become more and more difficult.

However, there are some actions that may help owners of older tanks achieve this, which are explained in the EPA’s “UST Technical Compendium: Financial Responsibility”.

One of the tips mentioned by EPA is to demonstrate compliance by maintaining thorough inspection, release detection and testing records.

Having a solution that can simplify and manage compliance complexity in one place is critical to help UST owners achieve this action. As mentioned before, iHUB features a full suite of compliance tools in one place providing comprehensive network visibility.

iHUB not only simplifies and centralizes compliance reporting but features customized workflows and analytics to understand exactly what happened and escalate priority alarms to avoid any fines or site shutdowns. This means more proactive and efficient compliance management, reduced site impact and lower maintenance spending.

Install refurbished assets

Given the high costs involved in installing new USTs or the difficulties in getting critical parts and materials, many tank owners are choosing to reuse a tank.

Most states have explicit requirements that should be fulfilled when doing this.

If UST owners are refurbishing or replacing sumps or tanks, they need to be certified by an independent testing organization before they are installed.

When it comes to sumps, Dri-sump testing has gained strong traction as a better alternative to conventional hydrostatic testing, since it uses no water, creates zero waste and will find leaks other water-based methods can’t, quicker, more accurately and conveniently.

According to our records, containment sumps fail at a rate of over 3%, based on a sample of 14,000 tests over 18 months, so clearly you shouldn’t leave a weak point in your fuel system component up to inferior test methods.

When it comes to new installations, our UST installation testing ensures a perfectly tight fuel system from day one. It is a Certified, accurate integrity testing at the pre-bury and post-bury stage for new site installations.

90% of new or remodelled sites that pass a gauge pressure test have an installation issue such as water ingress and small leaks from pipes, fittings and vents. If left undetected it can mean cutting up concrete, excavation, repair and possible remediation to fix a leaking installation.

UST installation testing at both the pre-bury and post-bury stages ensure you’re putting a 100% tight fuel system into the ground, protecting your multi-million dollar investment from the get-go.

How will you address the aging vessels?

What will happen with your USTs once they hit the 30-year mark? Will you keep your existing assets? Or move forward with other alternatives? Either way, we are here to help.

Get in touch with our team and we can discuss your strategy and how we can support you.